vickers hardness test report|vickers hardness testing machine diagram : maker (I) Aim: To determine the hardness of the given Specimen using Vickers hardness test. webCadastre-se grátis e encontre homens gays para um bate papo descontraído em nosso chat gay, câmeras ao vivo, vídeos e mais. E você? Está disponível? Se acha que isto está demorando mais do que o esperado, clique aqui! Cadastre-se grátis e encontre homens gays para um bate papo descontraído em nosso chat gay, câmeras ao vivo, vídeos .

{plog:ftitle_list}

Resultado da Leaked Regina Schneider reginaschneider_ rereschneider. Download full pack of her TikTok videos and photos. See her sexy and naughty side that .

vickers hardness testing machine diagram

The Vickers hardness test, which measures a material's resistance to deformation under a controlled load, is a commonly used technique to assess . The advantages of the Vickers hardness test is the extremely accurate readings can be taken and just one type of indenter is used for all types of metals. The Vickers test is capable of testing soft and hard material. The .

spi digital portable hardness tester

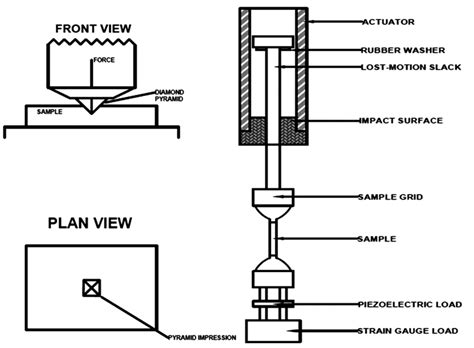

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h. (I) Aim: To determine the hardness of the given Specimen using Vickers hardness test.The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of which .

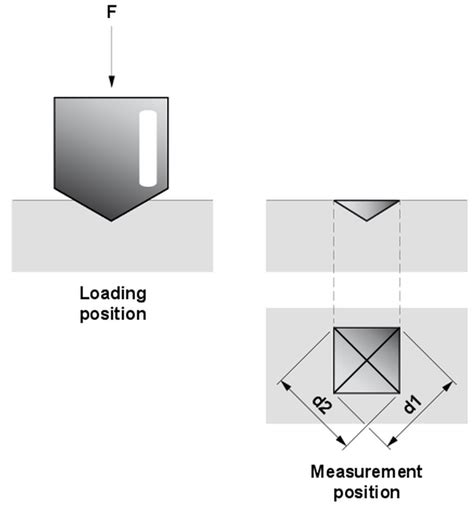

Vickers hardness should be reported like 800 HV/10, which means a Vickers hardness of 800, was obtained using a 10 kgf force. The advantages of the Vickers hardness test are that .Vickers Hardness Test. The Vickers hardness test utilises a diamond pyramid-shaped indenter to create a small impression on the material's surface. Taking into consideration the weight of the load, the size of the indentation is .

Designation: E92 − 17 Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials1 This standard is issued under the fixed designation E92; the number immediately following the designation indicates .The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the .Hardness Test 2/5 the microscope is in millimeters. The larger diameter indentation corresponds to a softer material and lower Brinell number. VICKERS HARDNESS TEST The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees

15.2.3.2 Hardness Test. A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N with a dwelling time of 12 s. Hardness measurements were performed on the cross-section surfaces of the rolled strips along the .Hardness test lab report objective to determine the hardness of various engineering materials using rockwell hardness test. to develop an understanding of. . Vickers Hardness Test; In Vickers test, it involves a diamond indenter . The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers. Low-load hardness testing is mainly used for testing of small .

1. rockwell hardness test 10 2. vickers hardness test 13 3. impact test 16 4. tensile test 21 5. compression test 26 6. shear strength test 29 7. heat treatment 32 8. wear test 35 9. microstructure 39 10. brinell hardness test 43 11. torsion test 46 12. fatigue test 49 13. bending test 53 14. ultrasonic test 56 15. magnetic particle test 58In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F[N]), the indentation on the sample is measured using a microscope.Vickers Hardness Testing Formulas, Calculator and Review . The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number ( HV ) or Diamond Pyramid Hardness ( DPH ). The hardness number can be converted into units of pascals , but .This Vickers hardness number calculator uses the size of indentation to return the hardness of the material. There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and Vickers hardness test.. The Vickers hardness scale, named after the company where it was developed in 1921, is the focus of this article.

Vickers is a hardness test for all solid materials, including metallic materials. The Vickers Hardness (HV) is calculated by measuring the diagonal lengths of an indent in the sample material left by introducing a diamond pyramid indenter with a given load. The diagonals of the indent are measured optically in order to determine the hardness .The Vickers hardness test uses a square base diamond pyramid as the indenter. The included angle between the opposite faces of the pyramid is l36°. The Vickers hardness tester . Attach the table as an appendix to your lab report!) 2. Using the above converted values, calculate the UTS and YS values using the empiricalThe application of hardness testing enables to evaluate a material properties such as strength, ductility and wear resistance. CONCLUSION: The Vickers hardness test is easy to use and its benefits far outweight any potential disadvantages include during the experiment of hardness testing with any type of material to measure the hardness of each .

Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Table 1: Different Hardness Test Methods and Their Corresponding Loads. Method Load Range Standard; Method. Brinell. Load Range. 1 kgf–3,000 kgf. Standard. ASTM E10, ISO 6506. Method.The Vickers hardness test was developed by RL. Smith and Sandland in 1921 at Vickers Ltd as an alternative to brinell hardness test method to measure the hardness of the material. The Vickers hardness test follows the brinell principle, in that an indenter of definite shape is pressed into the material to be tested, then the load is removed and .1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness testing machines (Part B), and the calibration of standardized hardness test blocks (Part C). Two general classes of standard tests are recognized:The Vickers method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6507, ASTM E92, ASTM E384).

The Vickers hardness number (HV) is calculated based on the indentation diagonal lengths. This method is suitable for a wide range of materials, including metals, ceramics, and plastics. Due to its small indentation size the Vickers . Mechanical hardness testing is fundamental in the evaluation of the mechanical properties of metallic materials due to the fact that the hardness values allow one to determine the wear resistance .PRACTICAL HARDNESS TESTING MADE SIMPLE Table of Contents Page 1. GENERAL 1 2. INTRODUCTION 3 3. BRINELL HARDNESS TESTING 9 4. VICKERS HARDNESS TESTING 14 5. ROCKWELL HARDNESS TESTING 17 6. INFORMATIONS 22 i PRACTICAL HARDNESS TESTING MADE SIMPLE 1. GENERAL Important facts and features to be known and .Data and Results: Table 1: Vickers Hardness Raw Data. Vickers Hardness Testing Lab. Material. Vickers Indentation Size for 30 kg Indentation Load Average HV 1st test 2nd test 3rd test d1 ± δ1 d2 ± δ2 d1 ± δ1 d2 ± δ2 d1 ± δ1 d2 ± δ2 d ± δ HV ± δ 6061-T6 Aluminum 735 724 747 728 734 103 1018 Cold Rolled Steel. 444 555 480 469 487 235

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.Download scientific diagram | Vickers hardness test: data on aluminum alloy. from publication: Indentation modulus at the macro-scale level measured by Brinell and Vickers indenters by using the .

For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the Vickers hardness values are comparable to a certain degree with the Brinell hardness values (applies to approx. 400 HBW or 400 HV). The .To ensure our progression in quality assurance, ATS’s Vickers Hardness Testing procedures abide by the ASTM E92 and ASTM E384 standards, for which we maintain ISO 17025 (A2LA) accreditation. With over 12,000 specifications developed by field experts, ASTM standards are internationally recognized, creating a basis of operations for service .

where α is the percentage crystallinity; H C is the hardness of fully crystalline PP, and H A is the hardness of fully amorphous PP. Using hardness testing with loads of 0.25 and 0.5 N and with a loading cycle of 0.1 min, Martinez Salazar et al. were able to extrapolate to show H C = 30 MPa and H A = 116 MPa. Whereas, this is useful information, there is ambiguity with . 2. VICKERS HARDNESS TEST The test makes the use of a diamond square based pyramid indenter with 136 angles between the opposite faces. The load range is variable from 5 to 120 kg in steps of 5 kg. It provides a continuous scale of hardness and so it is widely accepted for research works. Vickers hardness testing machine is somewhat similar to the .A square base pyramid shaped diamond is used for testing in the Vickers scale. Typically loads are very light, range from 10gm to 1kgf, although “Macro” Vickers loads can range up to 30 kg or more. 1 Objectives 2. Understand the preparation procedure of Vickers hardness testing. 3. Understand the concept of Vickers hardness testing. 4.

vickers hardness test procedure pdf

vickers hardness test procedure

spi electronic hardness tester

vickers hardness test pdf

my.anydesk II offers more secure and safer environment to utilize go.anydesk, enabling users to conveniently access the web client with advanced security. Enhanced protection against fraudulent behavior. By integrating go.anydesk into my.anydesk II, we are prioritizing user security and enhancing our protection against potential scams. .

vickers hardness test report|vickers hardness testing machine diagram